Acoustical Fiberglass Products

Acoustical Fiberglass

Acoustical fiberglass is a sound-absorbing material made from woven glass fibers, designed to reduce noise and improve room acoustics. Its porous structure helps absorb sound waves, reducing reverberation and controlling noise levels. It’s commonly used in spaces like offices, recording studios, theaters, classrooms, and industrial environments, where noise control is crucial. The material can be shaped into panels, tiles, or custom forms and is often coated with resin or fabric for durability and aesthetics. In addition to soundproofing, acoustical fiberglass also offers thermal insulation benefits, helping with temperature regulation. Its versatility makes it an ideal choice for creating quieter, more comfortable environments in both commercial and residential applications.

Benefits of Acoustical Fiberglass

Noise Reduction

Acoustical fiberglass is excellent at absorbing sound, making it ideal for noise reduction in commercial, industrial, and residential settings. Its porous structure traps sound waves, reducing echo and preventing sound transmission between rooms, resulting in quieter, more comfortable environments, which is particularly beneficial in busy or noisy spaces.

Thermal Insulation

Acoustical fiberglass also provides strong thermal insulation, helping to regulate indoor temperatures by reducing heat transfer. This makes it a cost-effective choice for improving energy efficiency in buildings. By minimizing heat loss or gain, it helps maintain consistent temperatures and reduces the need for excessive heating or cooling.

Fire Resistance

Acoustical fiberglass is naturally fire-resistant and can withstand high temperatures without catching fire. This quality enhances safety in buildings, particularly in commercial and industrial applications. Its non-combustible nature helps prevent the spread of flames, providing an added layer of protection and compliance with fire safety regulations.

Molded Acoustical Boards

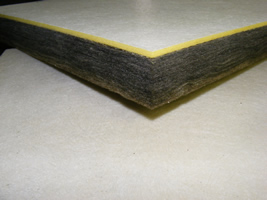

High Impact Boards

Designed for enhanced acoustical properties as well as meeting tackabililty and impact resistance requirements. Manufactured from UNCURED fiberglass. A variety of thicknesses, densities, mat facing and sizes are available.

- From 3/32″ to 1/2″

- 8 pound density to 20 pound density

- Plain or mat faced

- Facings available one or two sides

- Widths up to 62″, lengths to 145″

- Uncured fiberglass

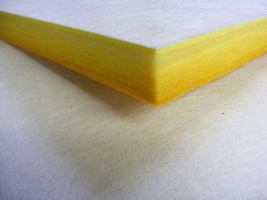

Dual Density Products

SRS Fiberglass Products can design and build sub assemblies and ship in customized thicknesses, densities and sizes.

Utilizing standard rotary manufactured acoustical board products from 3 pound density to 6-7 pound density or custom molded acoustical board, SRS Fiberglass Products will thermally bond Hi Impact molded board onto the acoustical core material and cut into finished sizes or standard blanks for your customers requirements.

- Reduced labor cost for customer

- Precut finished lengths and widths

- Thickness tolerances + or – to 0.030

- Consolidated thicknesses up to 2 1/2″ thickness

- Mat facings available for extreme smooth finishes

- Black or Amber Glass available

- Uncured fiberglass

Custom Molded Acoustical Board

Designed for non standard specification. SRS Fiberglass Products can design and build specialized products through heat and compression molding techniques. Unique thicknesses, densities, mat facings and sizes are available.

- 3/8″ thickness to 2″ thickness

- 2 pound density to 12 pound density

- Black or Amber glass available

- Facings available – one or two sides

- Hardened edges available

- Widths up to 62″, lengths to 145″

- Uncured fiberglass

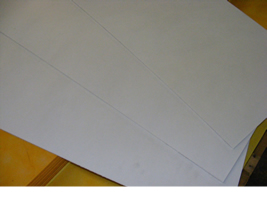

Multilayered Composite Tackboard

- High Degree of tackability, yet yields Superior Surface Characteristics

- Pure white color

- Durable, able to bend, withstand impact without board damage

- Can be made Formaldehyde Free if desired

- Manufactured using multiple layers of fiberglass mats or nonwovens

- Wide variety of thicknesses available

Contour Molded Thermal and Acoustical Materials

SRS Fiberglass Products can design, engineer and build proprietary tooling for heat/compression molding to your specialized requirements.

- Amber or Black fiberglass

- Facings available

- Raw Foil

- Foil Scrim

- Glass mat

- Poly rayon mats

- Uncured fiberglass

Fabricated Products

THERMAL and ACOUSTICAL products, light density 0.6 pound density to 7.0 pound density materials.

- Custom lamination of a variety of facing or materials

- Custom die cutting capability

- Semi Rigid Waffled board

- PF Resins and formaldehyde free products available

- Uncured fiberglass

- Metal Framing Assembly – unitized products